X射線技術用于快速評估花生性狀及關鍵品質

在印度,原料花生是由采集商從小農農場以整莢的形式獲得的,價格基于花生莢和果仁基本特性進行人工估計。這些原產品評估方法速度較慢,可能導致采購違規。采購延誤加上缺乏儲存設施,導致真菌污染,對許多地區的食品安全構成嚴重威脅。為了彌補這一差距,我們研究了X射線技術是否可以用于快速評估花生的關鍵品質,這些品質對價格評估很重要。

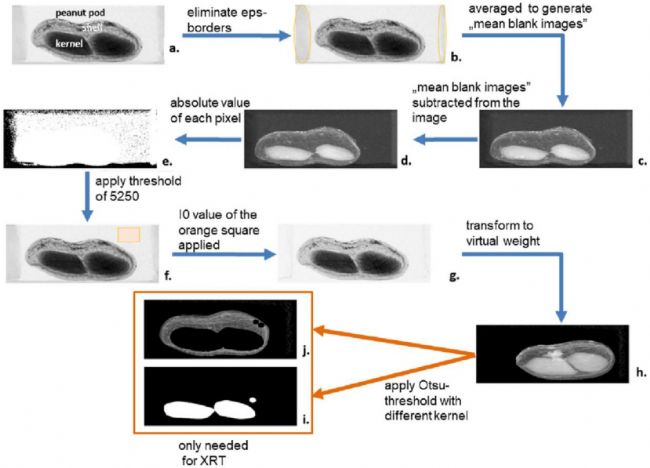

我們使用計算機斷層掃描(CT)系統生成了1752個花生莢2D X射線投影。在這些預測中,我們預測了核重和殼重,這是農產品價格的重要指標。測試了兩種特征預測方法:(i)X射線圖像變換(XRT)和(ii)經過訓練的卷積神經網絡(CNN)。這些方法的預測能力通過對不同花生莢果品種1的粒重和殼重的重量測量進行了測試。兩種方法都用R2預測了核質量 > 0.93(XRT:R2 = 0.93和平均誤差估計(MAE) = 0.17,CNN:R2 = 0.95和MAE = 0.14), 而CNN(R2)更準確地預測了外殼重量 = 0.91,MAE = 0.09)與XRT(R2)相比 = 0.78; MAE公司 = 0.08).

我們的研究表明,基于X射線的系統是估算花生生產關鍵指標的相關技術選擇(圖1)。所獲得的結果證明需要進一步研究,以適應現有的X射線系統,以實現快速、準確和客觀的花生采購過程。快速準確地估計農產品價值是避免真菌污染造成的收獲后損失的必要先決條件,同時允許向農民公平付款。此外,同樣的技術還可以幫助作物改良計劃,通過完全跳過豆莢脫殼過程,以高通量的方式選擇和開發具有更高經濟價值的花生品種。

本研究證明了該方法的技術可行性,是實現未來花生生產系統技術驅動轉型的第一步。

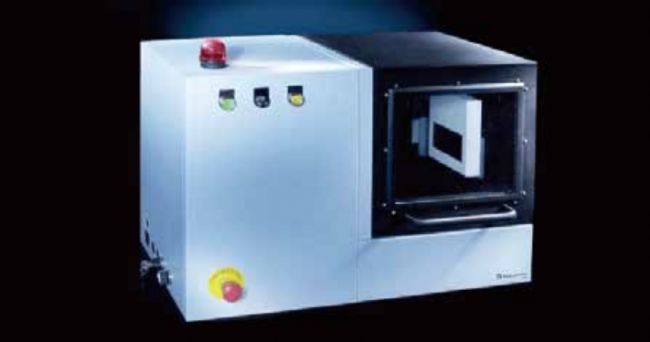

臺式CT斷層掃描儀用于植物根系、莖干、果實、種子、葉片等分析,為研究提供數據和進行數據分析。

臺式CT斷層掃描儀用于植物根系、莖干、果實、種子、葉片等分析,為研究提供數據和進行數據分析。

應用領域

臺式CT斷層掃描儀不僅運用于生物學,如植物根系、莖干、果實、種子、葉片等分析,也適用于地質學和考古學的大學或研究機構,也可用于對土壤結構如團粒結構等進行無損檢測,分析土壤和根系關系以及結構等。

臺式CT斷層掃描儀提供一種快速可視的物體內外結構三維模式,在生物學、工業無損檢測領域里變得越來越重要。

種子分析:玉米、小麥等

植物生長分析:葉片結構、根系結構等

土壤:土壤結構等

地理學和考古學:巖石樣品等

X-ray driven peanut trait estimation: computer vision aided agri-system transformation

Martha Domhoefer, Debarati Chakraborty, Eva Hufnagel, Joelle Claußen, Norbert Wörlein, Marijn Voorhaar, Krithika Anbazhagan, Sunita Choudhary, Janila Pasupuleti, Rekha Baddam, Jana Kholova & Stefan Gerth

Abstract

Background

In India, raw peanuts are obtained by aggregators from smallholder farms in the form of whole pods and the price is based on a manual estimation of basic peanut pod and kernel characteristics. These methods of raw produce evaluation are slow and can result in procurement irregularities. The procurement delays combined with the lack of storage facilities lead to fungal contaminations and pose a serious threat to food safety in many regions. To address this gap, we investigated whether X-ray technology could be used for the rapid assessment of the key peanut qualities that are important for price estimation.

Results

We generated 1752 individual peanut pod 2D X-ray projections using a computed tomography (CT) system . Out of these projections we predicted the kernel weight and shell weight, which are important indicators of the produce price. Two methods for the feature prediction were tested: (i) X-ray image transformation (XRT) and (ii) a trained convolutional neural network (CNN). The prediction power of these methods was tested against the gravimetric measurements of kernel weight and shell weight in diverse peanut pod varieties1. Both methods predicted the kernel mass with R2 > 0.93 (XRT: R2 = 0.93 and mean error estimate (MAE) = 0.17, CNN: R2 = 0.95 and MAE = 0.14). While the shell weight was predicted more accurately by CNN (R2 = 0.91, MAE = 0.09) compared to XRT (R2 = 0.78; MAE = 0.08).

Conclusion

Our study demonstrated that the X-ray based system is a relevant technology option for the estimation of key peanut produce indicators (Figure 1). The obtained results justify further research to adapt the existing X-ray system for the rapid, accurate and objective peanut procurement process. Fast and accurate estimates of produce value are a necessary pre-requisite to avoid post-harvest losses due to fungal contamination and, at the same time, allow the fair payment to farmers. Additionally, the same technology could also assist crop improvement programs in selecting and developing peanut cultivars with enhanced economic value in a high-throughput manner by skipping the shelling of the pods completely.

This study demonstrated the technical feasibility of the approach and is a first step to realize a technology-driven peanut production system transformation of the future.